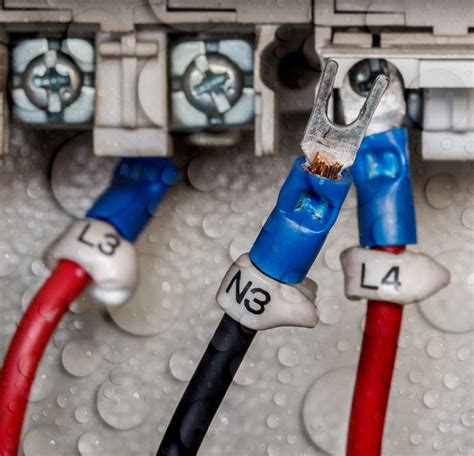

condensation in outdoor electrical enclosures The generation of condensation greatly reduces the insulation performance of the electrical enclosures electrical equipment, resulting in equipment damage and even casualties.

Here’s an in-depth guide to evaluating sheet metal bending machines for the utmost precision and accuracy, ensuring your projects soar to new heights. Factors to Consider. .

0 · how to prevent condensation in enclosures

1 · electrical enclosure condensation protection

2 · electrical condensation in enclosures

3 · condensation inside enclosure

4 · condensation in outdoor enclosures

5 · condensation in electrical storage

6 · condensation in dry enclosures

7 · condensation control enclosure

Van Scoyk Sheet Metal is a leader in fine custom metal cabinetry that has been serving the commercial industry for over 60 years. When it comes to choosing your metal cabinetry clients have the option of stainless steel, and steel.

Outdoor enclosures placed in environments with high humidity levels (such as coastal areas or rainy climates) are naturally more at risk for condensation, as are enclosures located in washdown locations or areas subject to indoor humidity. Outdoor enclosures can be some of the most vulnerable to condensation since they’re often installed in environments that have high humidity levels. If an enclosure isn’t protected from moisture ingress, condensation can . Without effective electrical-enclosure moisture control, condensation can form. For outside electrical cabinets and electrical housings, this is especially dangerous in sub-freezing . Condensation inside electrical enclosures can cause several problems, such as corrosion, short-circuiting, and equipment failure. By understanding how condensation occurs, you can take steps to prevent it and .

Preventing condensation inside an electrical enclosure Here are three top tips: 1. Position the enclosure away from any temperature fluctuations (such as direct sunlight or engines, for .The generation of condensation greatly reduces the insulation performance of the electrical enclosures electrical equipment, resulting in equipment damage and even casualties.

Condensation is caused by hot, humid air coming into contact with a colder surface than the air dew point. With Spring’s typical variable weather conditions, outdoor enclosures are even more exposed to the risk of .Condensation in outdoor enclosures creates problems: it can fog, blur or dim lenses, and threaten to corrode electronic components. This can compromise the performance and lifespan of .

You already saw how temperature impacts condensation. Beyond where you put the electrical enclosure, you have methods and tools that can help you stabilize the internal temperature. Heating or climate control systems can .Outdoor enclosures placed in environments with high humidity levels (such as coastal areas or rainy climates) are naturally more at risk for condensation, as are enclosures located in washdown locations or areas subject to indoor humidity. Enclosures that are tightly sealed and large enough to allow airflow reduce the risk of condensation. Essentially, however, you prevent condensation by keeping relative humidity below 60% and controlling sudden temperature variations.

Outdoor enclosures can be some of the most vulnerable to condensation since they’re often installed in environments that have high humidity levels. If an enclosure isn’t protected from moisture ingress, condensation can accumulate on . Without effective electrical-enclosure moisture control, condensation can form. For outside electrical cabinets and electrical housings, this is especially dangerous in sub-freezing temperatures. Condensed water freezes, and then turns to frost. Condensation inside electrical enclosures can cause several problems, such as corrosion, short-circuiting, and equipment failure. By understanding how condensation occurs, you can take steps to prevent it and protect your electrical systems.

Preventing condensation inside an electrical enclosure Here are three top tips: 1. Position the enclosure away from any temperature fluctuations (such as direct sunlight or engines, for example) 2. Avoid any very damp location (such as by the sea or near large areas of water pooling) 3. Add ventilation or heating device to the enclosureThe generation of condensation greatly reduces the insulation performance of the electrical enclosures electrical equipment, resulting in equipment damage and even casualties.

Condensation is caused by hot, humid air coming into contact with a colder surface than the air dew point. With Spring’s typical variable weather conditions, outdoor enclosures are even more exposed to the risk of condensation. Condensation can also occur indoors if the humidity is too high.

Condensation in outdoor enclosures creates problems: it can fog, blur or dim lenses, and threaten to corrode electronic components. This can compromise the performance and lifespan of everything from outdoor lighting, security cameras or control panels to solar, energy-grid components or telecommunication systems, as well as heavy-duty equipment. You already saw how temperature impacts condensation. Beyond where you put the electrical enclosure, you have methods and tools that can help you stabilize the internal temperature. Heating or climate control systems can fit inside some enclosures, making condensation management a snap.Outdoor enclosures placed in environments with high humidity levels (such as coastal areas or rainy climates) are naturally more at risk for condensation, as are enclosures located in washdown locations or areas subject to indoor humidity.

how to prevent condensation in enclosures

Enclosures that are tightly sealed and large enough to allow airflow reduce the risk of condensation. Essentially, however, you prevent condensation by keeping relative humidity below 60% and controlling sudden temperature variations.

Outdoor enclosures can be some of the most vulnerable to condensation since they’re often installed in environments that have high humidity levels. If an enclosure isn’t protected from moisture ingress, condensation can accumulate on . Without effective electrical-enclosure moisture control, condensation can form. For outside electrical cabinets and electrical housings, this is especially dangerous in sub-freezing temperatures. Condensed water freezes, and then turns to frost. Condensation inside electrical enclosures can cause several problems, such as corrosion, short-circuiting, and equipment failure. By understanding how condensation occurs, you can take steps to prevent it and protect your electrical systems.

Preventing condensation inside an electrical enclosure Here are three top tips: 1. Position the enclosure away from any temperature fluctuations (such as direct sunlight or engines, for example) 2. Avoid any very damp location (such as by the sea or near large areas of water pooling) 3. Add ventilation or heating device to the enclosure

The generation of condensation greatly reduces the insulation performance of the electrical enclosures electrical equipment, resulting in equipment damage and even casualties. Condensation is caused by hot, humid air coming into contact with a colder surface than the air dew point. With Spring’s typical variable weather conditions, outdoor enclosures are even more exposed to the risk of condensation. Condensation can also occur indoors if the humidity is too high.Condensation in outdoor enclosures creates problems: it can fog, blur or dim lenses, and threaten to corrode electronic components. This can compromise the performance and lifespan of everything from outdoor lighting, security cameras or control panels to solar, energy-grid components or telecommunication systems, as well as heavy-duty equipment.

electrical enclosure condensation protection

$20.99

condensation in outdoor electrical enclosures|electrical condensation in enclosures